FLAKED EPOXY FLOORING

Durability with texture, traction, and style.

Flaked epoxy flooring—also known as decorative chip or broadcast flake flooring—is a multi-layered epoxy floor system that incorporates colored vinyl flakes for added texture, visual interest, and slip resistance. It’s a favorite for garages, basements, commercial spaces, and workshops thanks to its clean, professional appearance and rugged performance.

This system combines functionality, safety, and aesthetic versatility, making it a practical and attractive choice for both residential and commercial environments.

What Is Flaked Epoxy Flooring?

Flaked epoxy flooring is a resin-based floor coating where colored vinyl flakes are broadcast into a base layer of epoxy, then sealed with one or more top coats. The flakes add texture and dimension while also helping to hide dirt, dust, and imperfections—making this floor not only attractive but extremely low-maintenance.

Flake sizes and color blends can be fully customized, offering finishes that range from neutral and industrial to bold and modern.

IDEAL FOR

-

Garage

Durable, resists oil, grease, and tire marks.

-

Basements

Moisture-resistant, easy to clean, and aesthetically versatile.

-

Commercial Spaces

Withstands heavy foot traffic, customizable for branding.

-

Warehouse & Workshops

Tough against tools, chemicals, and spills.

-

Showrooms

Polished look with flake designs for visual appeal.

-

Bathrooms & Locker rooms

Waterproof and mold-resistant.

BENEFITS OF flaked

EPOXY FLOORing

Slip-Resistant

The flake texture adds traction, making it safer in wet or high-traffic areas.

Durable & Long-Lasting

Resistant to chemicals, oil, salt, hot tires, and heavy impact.

hides Imperfections

The flake system conceals minor flaws, stains, or uneven areas in the concrete.

Custom color option

Choose from pre-made blends or create your own custom mix to match your space.

Easy to clean & Maintain

Seamless surface prevents dirt buildup and allows for quick cleaning.

UV-Stable with polyaspartic top coat

Won’t yellow or fade in sunlight when properly sealed.

How It’s Done

Our 5-Step Process

-

We diamond grind or shot blast the concrete surface to open the pores for strong adhesion. Any cracks or damage are repaired.

-

A tinted epoxy base is applied, which helps anchor the flakes and match your chosen color theme.

-

While the base coat is still wet, decorative flakes are broadcast across the surface—either lightly (partial) or fully (100% broadcast) for full coverage.

-

Once the floor cures, we scrape and vacuum to remove loose or excess flakes, ensuring a smooth, even texture.

-

A UV-stable, protective top coat (typically polyasparticor polyurethane) is applied to seal the flakes, enhance durability, and add gloss or matte finish as desired. Anti-slip additives can be included upon request.

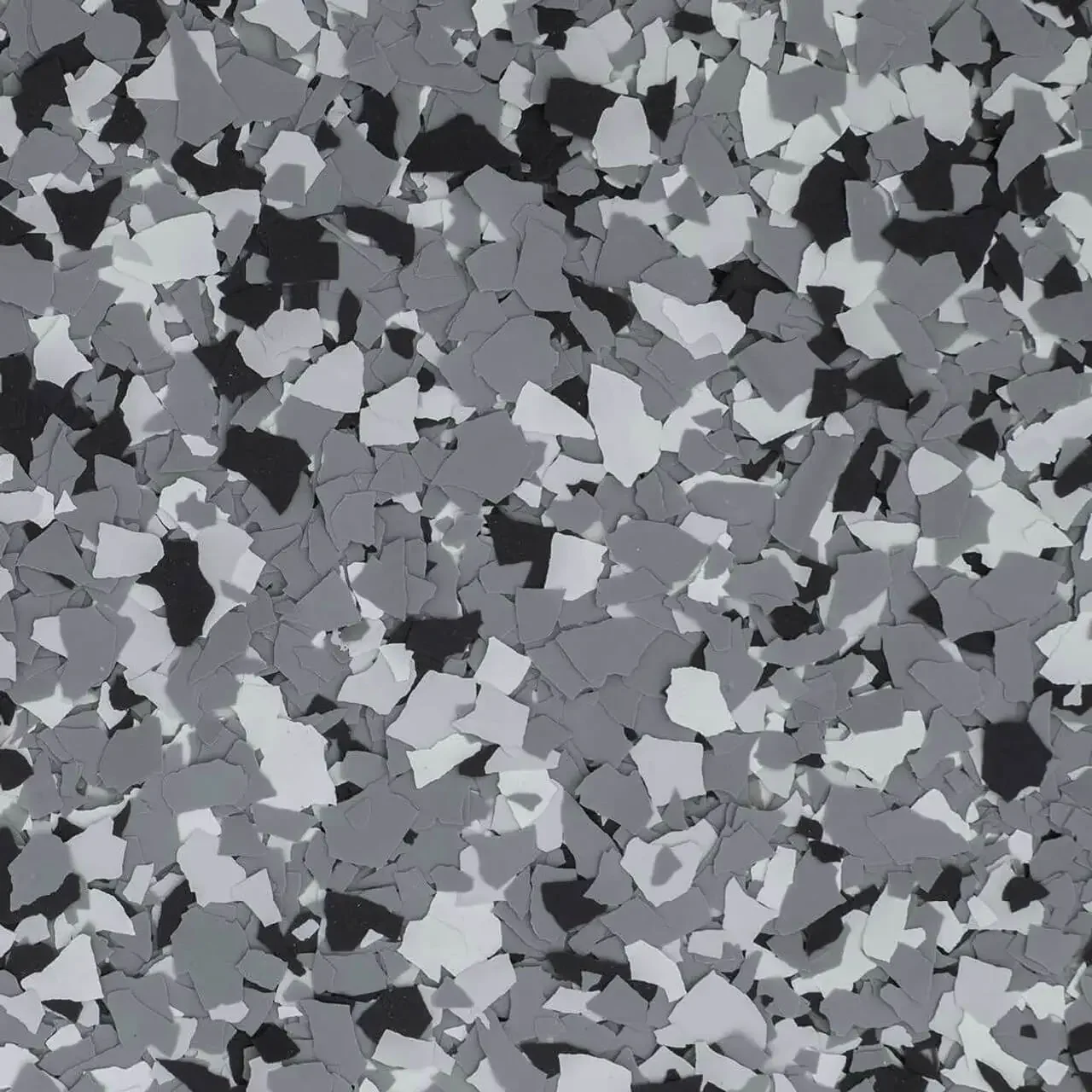

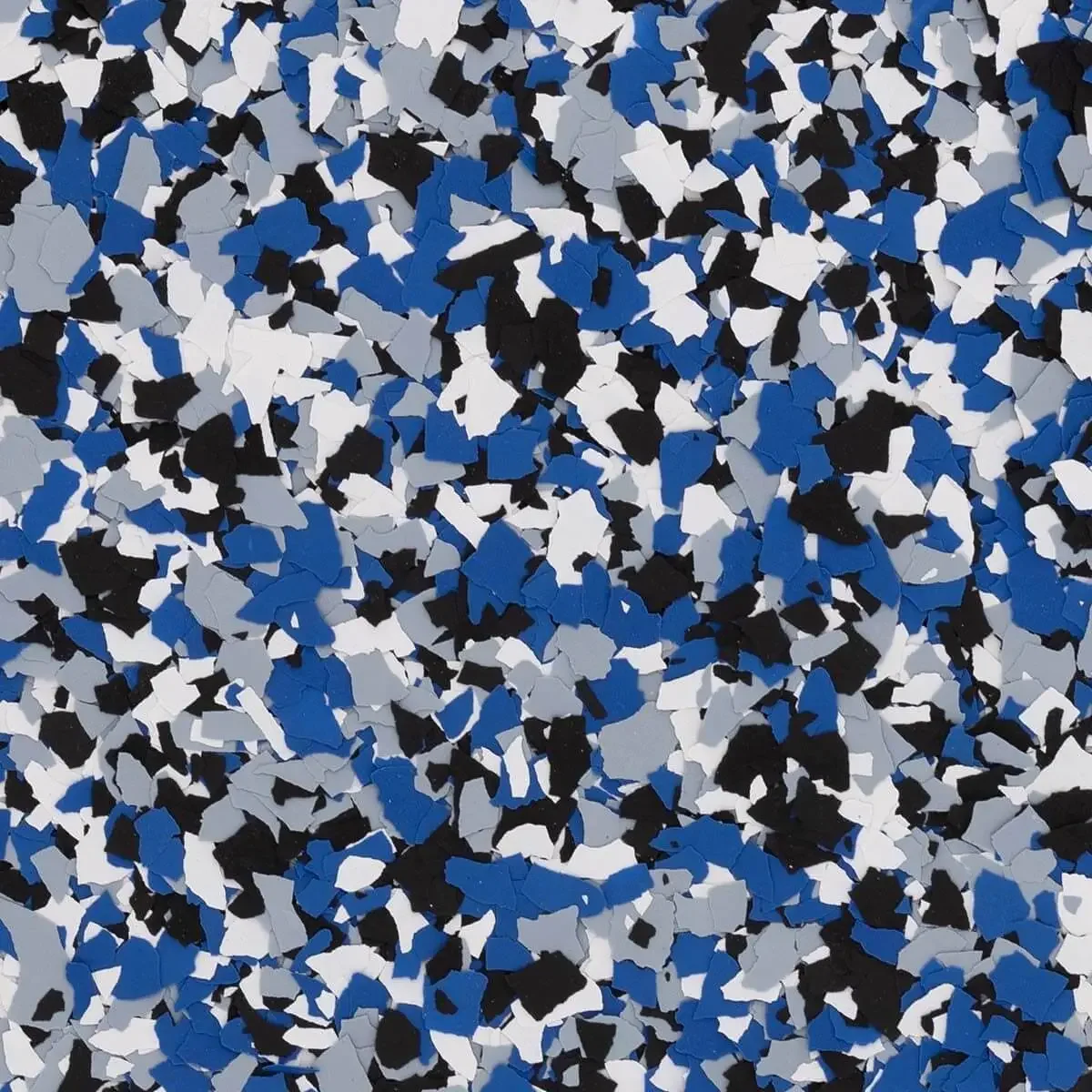

Color Options

-

CABIN FEVER

-

DOMINO

-

WOMBAT

-

CREEKBED

-

ORBIT

-

NIGHTFALL

-

SHORELINE

-

GRAVEL

-

OUTBACK

-

TIDAL WAVE

Whether you’re upgrading a garage, basement, showroom, office, or commercial space, Flaked Epoxy brings both beauty and resilience underfoot

why choose flaked Epoxy Flooring ?

If you're looking for a low-maintenance, durable, and visually clean flooring solution that offers a little more texture and grip than traditional epoxy, flaked epoxy is a top-tier option. Our team works with you to choose the ideal color and flake blend that matches your space—and delivers long-lasting performance you can trust.